electrical discharge machining puzzle

In fact the workpiece isnt touched by a tool at all. Sale ends tonight at midnight EST.

Wire Edm Electric Discharge Machining Medical Tooling Machining Hitachi Cable America

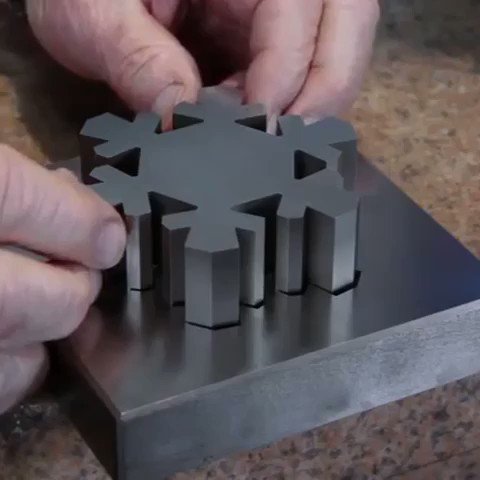

Electrical discharge machining leads to these perfectly fitted steel puzzles.

. Crossposted by 3 years ago. Electric Discharge Machining EDM is a subtractive machining process that uses electrical current to. Extremely high precision CNC wire cut machine with a finish of 06 µ Ra.

That allows the metal to be cut in such a precise way that two parts can merge seamlessly. Presenting an elongate electrode to the workpiece with a spark gap therebetween. Choose your favorite electrical discharge puzzles from thousands of available designs.

This process is done by applying high-frequency current through electrodes and Workpiece emerging in the dielectric fluid. Electric discharge machining is a non-conventional machining process that uses an electric spark to remove metal from the workpiece. Learn more about electrical discharge machining EDM and the various types of EDM available in our introductory guide.

The electric spark produces intense heat of 14000 to 21500F. Fundamentally the electric erosion effect is defined as the breakdown of electrode material that. This is how an electro-discharge machine looks like.

It is also known as Spark erosion Electro-erosion or spark machining. EDM is a non-traditional manufacturing process that uses thermal energy to remove material from a workpiece as opposed to mechanical force. Electricity is zapped through it produces a spark.

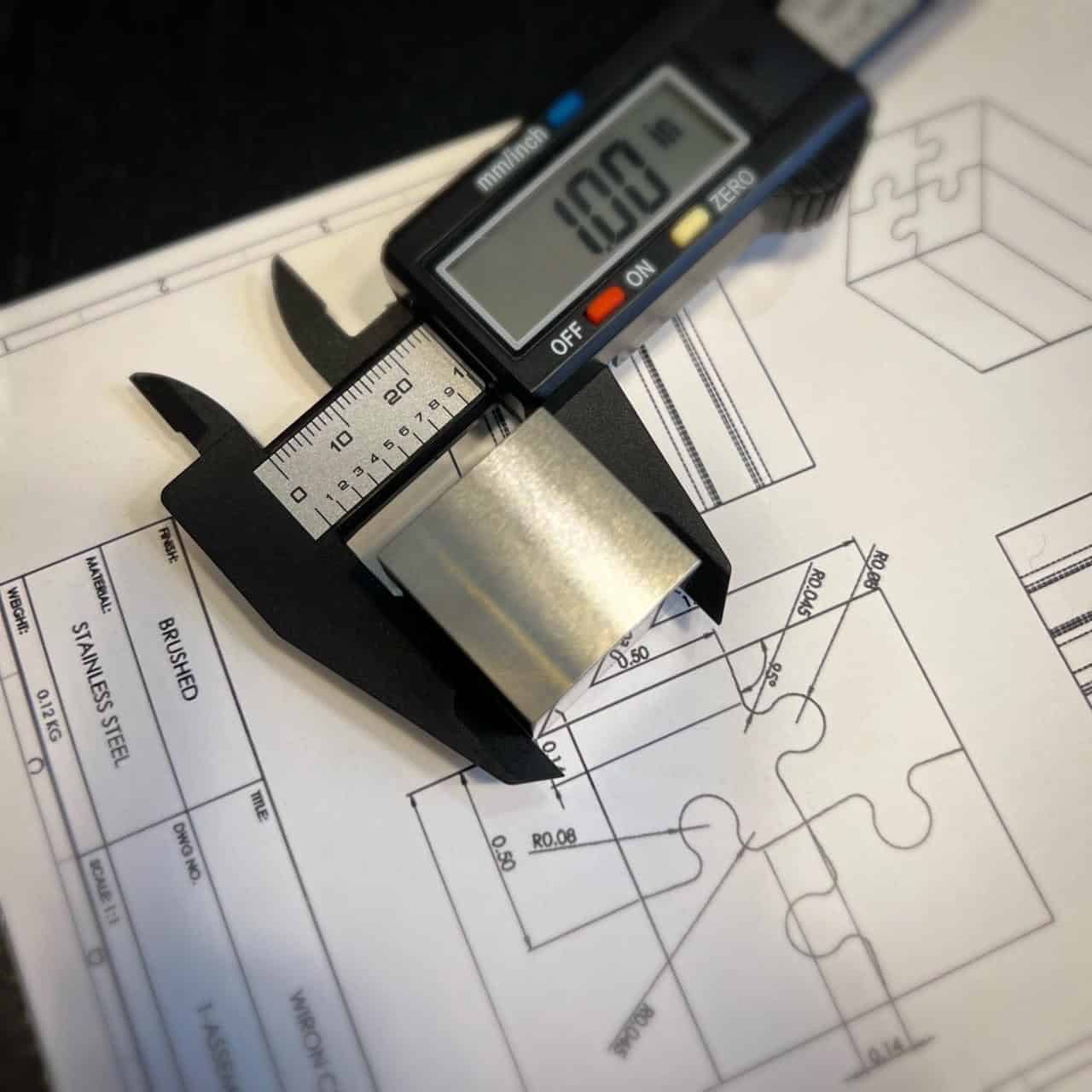

Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes separated by a dielectric liquid. Wiron Cube The Oddly Satisfying EDM Puzzle Pieces Experience the satisfaction of advanced wire EDM jigsaw puzzle. Your mission in this electrical puzzle is to light the evening city.

Everybody wants to be a superhero. But today could be that. This helps to create holes of various small dimensions.

It intends to provide an overview of how this process works when it should be used and what design considerations must be made. Extremely high precision CNC. It is used for producing hole size less than 01 mm.

Here are some applications of Electrical Discharge Machining. Electrical discharge machining tends to work to very tight tolerances of - 0012mm. Instead a high-frequency electrical charge disintegrates the material molecule by molecule to make a sharp cut.

Electrical discharge machining leads to. Choose your favorite electrical discharge puzzles from thousands of available designs. Electrical Discharge Machining is also called or known as Spark machining spark eroding burning die sinking wire burning or wire erosion.

Electric discharge machining also known as spark erosion electro-erosion or spark machining is a metal removal process that uses an interrupted electric spark discharge between the electrode tool cathode and the work anode to erode metals. Flowing a dielectric fluid in the gap. Electrical discharge machining is a highly precise manufacturing process that uses electricity to remove materials from the workpiece instead of a cutting tool.

Electrical discharge machining is a quick and unique way to create accurate deep small holes drilling in materials regardless of their hardness. This spark near to 8000 to 12000º C. Electrical Discharge Machining EDM is commonly used as non-traditional manufacturing methods for geometrically complex shaped or hardened materials that are extremely difficult.

Displacing the electrode in a direction aligned with the long axis of the electrode to. Holes in the air brakes or Pneumatic Brakes were done by an electrical discharge machining process. A method for electrical discharge machining a workpiece includes the steps of.

Engineers often turn to EDM when machining processes such as CNC milling and turning. But some of us have to be electricians. The hole drilling process involves using a brass electrode tube to channel the electrical discharges onto the material.

Northern Gauge has the capability to wire cut EDM pieces with 400 x 300 mm XY range and with a Z axis range of 250mm. Learn even more about how the proce. This is a manufacturing operation in which we used to make desired shapes by using an electrical spark.

All electrical discharge puzzles ship within 48 hours and include a 30-day money-back guarantee. Used for die sinking or die manufacturing. Not only do we have the ability to wire cut with precision but we have the metrology lab to back it up and provide.

In EDM or electrical discharge machining theyre not physically touching the parttheyre machining with lightning bolts literally sparks. This is a significant characteristic that makes it applicable in the aerospace and medical industries. Gaze Upon the Black Magic of Electrical Discharge MachiningITS NOT EVERY day that industrial machining sends you into a fit of joy.

20 off all products. What is Electric Discharge Machining. Electrical discharge machining is an effective manufacturing solution for machining applications with high requirements.

The blasts come with extremely high frequency something like 20000 sparks per second along the length of a brass wire. Electrical discharge machining EDM also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication process whereby a desired shape is obtained by using electrical discharges sparks. Quickly attach together a contact out of numerous wire pieces and get a faerie electrical discharge.

Eroding the workpiece by electrical discharge between the tip of the electrode and the workpiece. Electrical discharge machiningEDM cuts metal using a superfine brass wire. Our machine shop can cut metal so precisely using our wire EDM that two parts fit together with virtually no gap between.

All electrical discharge puzzles ship within 48 hours and include a 30-day money-back guarantee.

Mersen Electrical Discharge Machining Edm

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

Amazing Cube And Sphere Made By Wire Cut Edm Machine Youtube

Oh Wow Watch A Bunch Metal Shapes Created Using Electrical Discharge Machining Fit Together Seamlessly Dr Wong Emporium Of Tings Web Magazine

Zero Tolerance Machining With The Wire Edm Making A Puzzle Cube Part 2 Us Digital Youtube

Electrical Discharge Machining Leads To These Perfectly Fitted Steel Puzzles R Engineeringporn

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

Fabrication Vacuum Technology Inc

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

World Of Engineering On Twitter Amazing Accuracy Of Electrical Discharge Machining Wire Edm Can Cut With Accuracies Of 0001 00254 Mm Worldofengineering Engineering Technology Edm Machining Source Reliableedm Youtube Https T Co

High Quality Wire Cut Edm Wire Cutting 25mm 25mm Skd11 Steel Puzzle Parts Milling High Polished Buy Wire Cut Edm Edm Wire Wire Edm Wire Product On Alibaba Com

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

Gaze Upon The Black Magic Of Electrical Discharge Machining Wired

Mitsubishi Wire Edm Puzzle Pieces Youtube

Gaze Upon The Black Magic Of Electrical Discharge Machining Wired